ANTENNA

Our customers in the antenna industry come from various fields, including semiconductor, automotive, industrial, consumer electronics, enterprise devices, satellite communications, telecom, and transportation domains, but they all share one common goal: finding solutions that fit their specific needs. This is where Sasken steps in, offering a flexible and honest design partnership to meet those needs.

Offering Overview

The antenna is the heart of every wireless product. However, the antenna is a challenging component to design due to its complicated nature of the interplay of electromagnetic phenomena between the antenna and its surroundings. Design is often an iterative cycle of studies, simulations, measurements and modifications to find the optimal solution for the customer's need. Optimal is often perceived as the “best” but in antenna design it is more about finding a balance in performance with competing different antenna properties such as efficiency, bandwidth, radiation pattern, size or cost.

Where is this offering applied?

Antennas are essential in telecommunications, broadcasting, wireless networking, satellite communication, radar, navigation, automotive, and military applications.

The value chain comprises R&D, manufacturing, distribution, sales, installation/integration, maintenance/support, and upgrades/innovation. It also involves designing, manufacturing, distributing, installing, and maintaining antennas to ensure reliable wireless communication across industries and applications.

Addressing customer needs

Our customers come to us with issues in, for example efficiency, bandwidth, radiation pattern, size or cost. They might require greater range, wish to reduce the antenna noise temperature or change the existing single band to multiband antenna. We also solve issues such as fitting the antenna into a smaller enclosure, finding better materials for customers antenna or integrating several antennas.

A closer look at Sasken offerings

We offer complete antenna design from specification and initial concept to complete mechanical and electrical design. We can also assist in production related matters. Our unique in-house antenna measurement capabilities and close collaboration with our mechanical and RF engineers offer the best value for our customers' investment. Our in-house capabilities also allow efficient protype manufacturing including PCB milling, 3D printing and CNC milling. More complex high-quality PCB, flex and sheet metal prototypes are available from our suppliers within a few weeks.

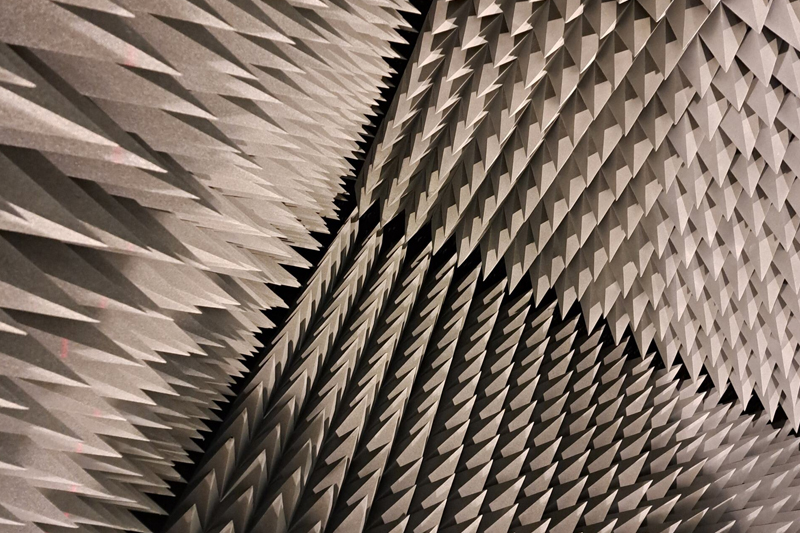

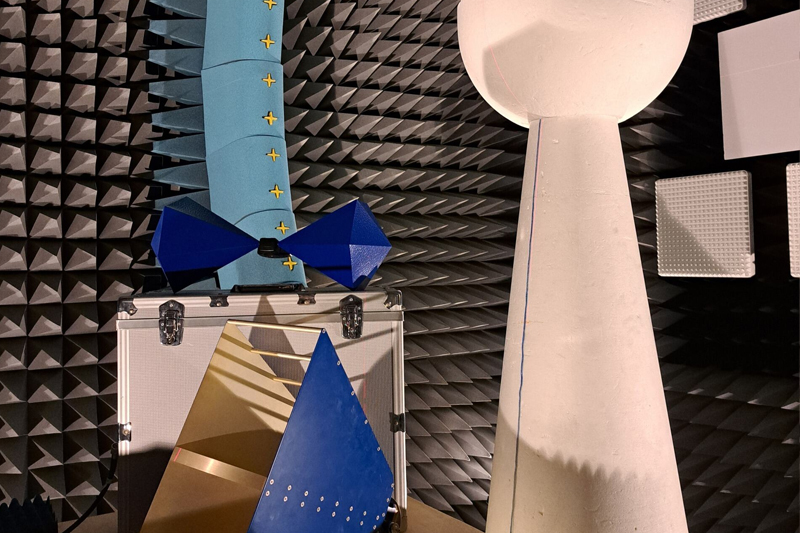

Laboratories and testing facilities

The independence of 3rd-party lab schedules gives us quick turnaround in the design cycle and the chance to study and solve issues immediately. At our Kaustinen site, we use Satimo SG64L test system for radiated testing, which allows high speed passive testing up to 6GHz in the anechoic chamber.

This system covers efficiency, peak gain, polar 2D radiation pattern, 3D radiation pattern, and more. Active testing is also feasible for cellular systems (TRP, TIS), with a maximum DUT size of approximately 179cm (70½in). Preparing measurements for devices and conducting return loss (S11) measurements using a network analyzer are part of our conductive testing capabilities. We can also conduct isolation measurements between antennas and capture S-parameters for simulations. Moreover, we possess some 75-ohm measurement capabilities.

Tools and technologies utilized

For antenna simulations, we utilize CST Studio Suite 3D EM simulation and analysis software, seamlessly integrated with our mechanical engineers' CAD tools. This allows us to import and export virtually any 3D files for thorough performance analysis and optimization. PCB prototypes are milled in-house with our LPKF Protomat S62 with system resolution of 0.25 um (0.01 mils).

CASE STUDY

FM radio reception improvement

Read More →

Bluetooth antenna performance

Read More →

Next Generation LTE-over-Satellite Product Family

Read More →