PRODUCTION TESTER

Our customers in the production testing industry range from major international corporations to small local businesses, each with distinct and specialized requirements.

Offering Overview

During the manufacturing process, ensuring production quality through testing of products, parts, or components is essential. Sasken provides solutions for this by identifying required test cases, designing testing solutions, and ultimately constructing and deploying production testers onto the production line at the customer's manufacturing facility.

Where is this offering applied?

Quality assurance in manufacturing occurs at the culmination of the product creation process. Its primary objective is to ensure that manufacturing operations adhere to specified standards and requirements. The extent and focus of production testing are contingent upon the nature of the manufactured goods, with its presence evident across all levels of production.

Addressing customer needs

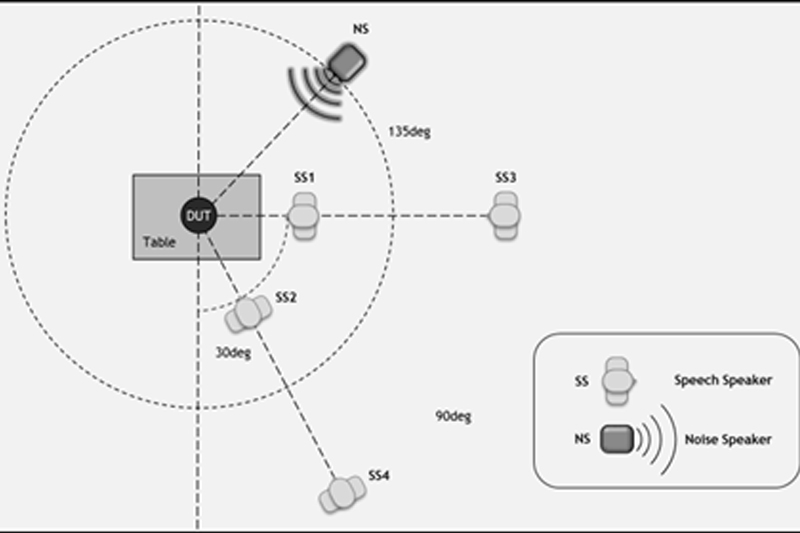

Sasken addresses customer challenges by offering turn-key solutions for production testing. This means examining critical components like fully assembled PWB/PCBA boards, as well as calibrating and testing wireless communication functionalities—cellular, Bluetooth, WiFi. Automated RF performance calibration and verification are conducted using production testers.

A closer look at Sasken offerings

Sasken excels in automated testing solutions for electronic components at all levels, from boards to products. We offer R&D, production, and maintenance tester solutions. Our tester system, started in 2000 with RF Performance software, is now the STSP, in its third generation.

Sasken offers a wide array of testing solutions, including PCB/PWB board testers for single and multi-board setups, along with solutions for antennas, RFIDs, displays, HiPots, Multi-signal testers, and more. Our testing scope encompasses product features, audio quality, camera performance, and specialized assessments like conductivity of device coatings.

Sasken's testing infrastructure is based in Finland, with global commissioning at customer factories. We prioritize providing thorough support and spare parts for our testers to ensure smooth operations and customer satisfaction.

Laboratories and testing facilities

The existing Tester Software platform utilizes NI LabVIEW and TestStand as its foundation, complemented by modules written in C, C#, and Python. These software tools offer remarkable flexibility and efficiency for system development, accommodating all necessary modules and functions.

Our testing setup also incorporates a diverse array of commercially accessible measurement devices, along with proprietary developments. In certain scenarios, we integrate customer-provided equipment as dictated by the specific requirements of the testing solution.

Case Study

Audio Production Tester

Read More →

Production Testers for Satellite Terminals

Read More →

Production Tester for Routine tests

Read More →