PRODUCT LIFETIME MANAGEMENT

Sasken caters to clients across various sectors, including manufacturing, automotive, aerospace, healthcare, and consumer electronics, where the effective management of intricate product lifecycles is crucial, relying on PLM solutions.

Offering Overview

Product Lifecycle Management (PLM) covers the full management of a product’s journey from inception, through design, manufacturing, distribution, and ultimately to its end-of-life phase. This requires tasks such as product data management, configuration management, quality assurance, compliance oversight, and facilitating collaboration among diverse stakeholders engaged throughout the product's lifecycle.

Where is this offering applied?

Product Lifecycle Management (PLM) solutions play a crucial role in various industries such as manufacturing, engineering, healthcare, consumer goods, and energy. They optimize operations from design conception to post-sales support, guaranteeing efficiency, regulatory adherence, and product excellence. By overseeing data management and refining supply chains, PLM accelerates time-to-market while elevating customer contentment, ultimately fostering business success.

Addressing customer needs

PLM involves grappling with many hurdles for our customers. These include efficiently handling extensive product data covering designs and specifications, orchestrating collaboration among geographically dispersed teams, ensuring smooth communication and version control, adhering to regulatory standards and compliance throughout the product lifecycle, overseeing global supply chains, sourcing components, and streamlining logistics.

A closer look at Sasken offerings

Our Product Lifecycle Management solutions are integral in facilitating the smooth management of our clients' products from inception to end-of-life.

This includes optimizing product data management, maintaining robust configuration control, implementing rigorous quality assurance measures, overseeing compliance diligently, and promoting collaboration among all stakeholders throughout the product's lifecycle.

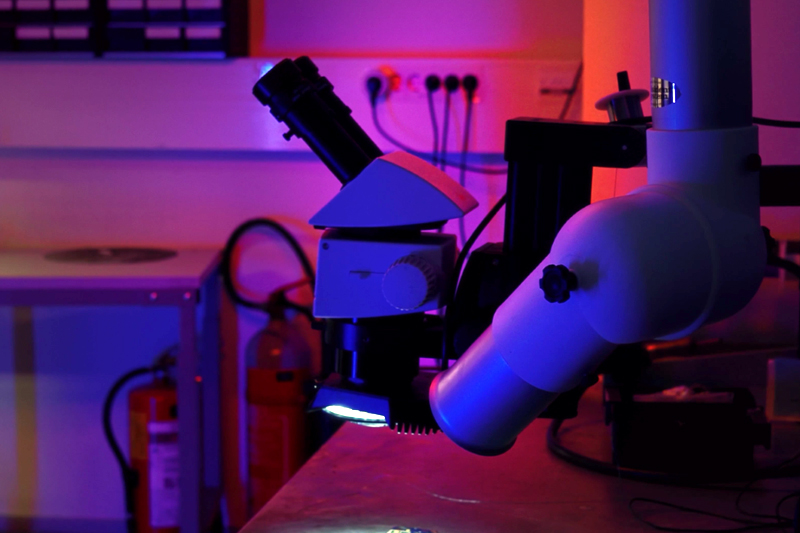

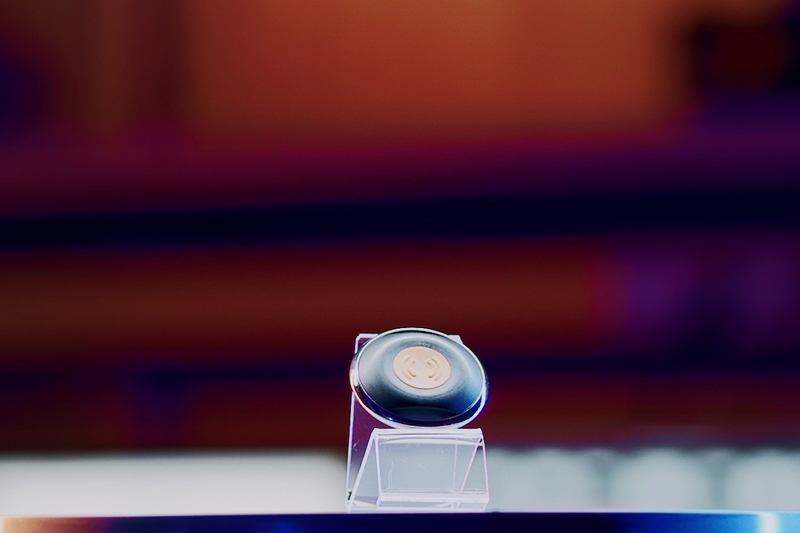

Laboratories and testing facilities

Our laboratories are fully equipped to verify electronic devices, enabling us to conduct precise measurements to ensure adherence to specifications. Additionally, we offer verification services for our clients' designs, providing valuable feedback on their performance.

In our toolset, we leverage various software solutions, with our current Tester Software platform being constructed on NI LabVIEW and TestStand. Complemented by modules in C, C#, and Python, these tools afford us the flexibility and efficiency needed for comprehensive system development, ensuring the fulfillment of all required modules and functions.

Case Study

Air quality map tool

Read More →

Testing services

Read More →

Air Quality

Map Tool

Read More →