TECHNOLOGY AND BRAND ANALYSIS

We employ indirect means like thermal imaging and near-field probing to assess functionality. Furthermore, we offer application development services to navigate scenarios where conventional testing or engineering mode software is unavailable.

Offering Overview

Technology and brand analysis offer investment protection, a competitive edge, and support monetization. By ensuring fair and reasonable terms, we help our customers maximize the value and impact of their investments.

Where is this offering applied?

Companies require technology and brand analysis to assess the technological progress within their industry. This helps to understand the competitive landscape, identify innovation opportunities, and make informed decisions on research, development, and investment strategies.

Addressing customer needs

Common challenges include navigating multilayer PCB structures, safely decapsulating components without damaging silicon and bonding wires, examining microscopic structures on materials and surfaces, and visualizing embedded structures within mechanical parts.

A closer look at Sasken offerings

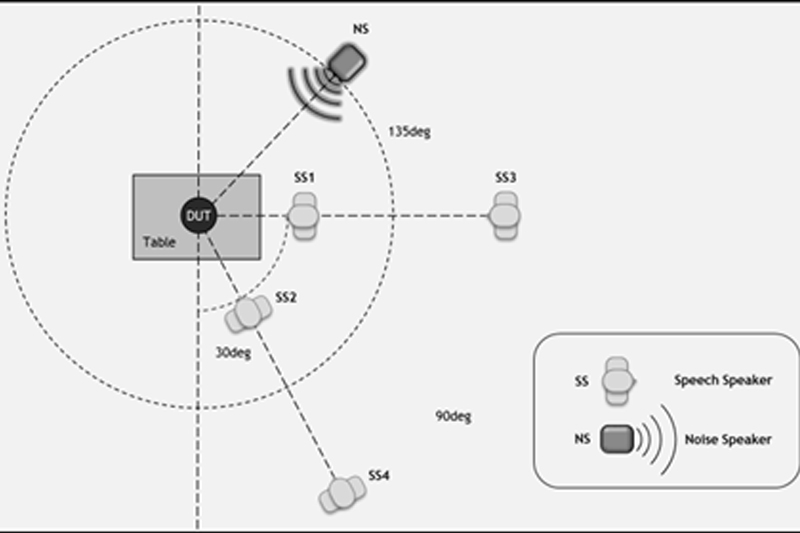

We possess established techniques, methodologies, and instruments for assessing product designs, structural intricacies, and functionalities to detect potential issues. At Sasken, we integrate various approaches, such as reverse engineering to gauge elusive signals, scrutinizing schematics and board layouts, conducting cross-sectioning and component decapsulation analyses. We also use indirect means like thermal imaging and near-field probing to assess functionality. Furthermore, we offer application development services to navigate scenarios where conventional testing or engineering mode software is unavailable.

Laboratories and testing facilities

We specialize in technology and brand analysis, including reverse engineering, technology replication, and identification of intellectual property and trademark issues. Our services include competitor product analysis, destructive physical analysis, and comprehensive quality documentation.

Additionally, we offer teardown analysis, conducting Bill of Materials (BOM) and feature identification, employing techniques such as X-Ray imaging, optical and scanning electron microscopy, and high-resolution photography.

Case Study

Testing services

Read More →

Environmental and Durability Testing

Read More →

EMC Verification and Troubleshooting

Read More →