MECHANICS

If a customer faces a mechanical design challenge, we can offer the solution, whether it involves a single phase of the mechanical design lifecycle or if the customer requires us to take responsibility for the entire product lifecycle.

Offering Overview

Mechanical design transforms an idea into an actual product. Sasken provides experienced mechanical design from scratch: conceptual and ID design, until the end-of-life product lifecycle support, including all the steps in between: detailed design, product testing and manufacturing support.

Where is this offering applied?

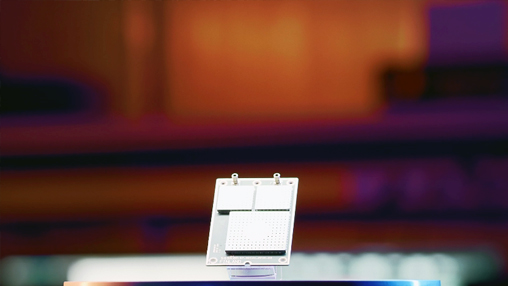

Mechanical design serves as the foundation of hardware design, connecting various aspects throughout the product lifecycle and interconnecting different hardware design domains such as antenna design, layout design, and PCB design.

It plays an important role across all phases of the product lifecycle, spanning design, manufacturing, logistics, testing, and extends even to after-market services.

Addressing customer needs

The typical challenges from our customers include implementing all necessary features in the smallest possible package, creating a product that is both feasible and durable in a harsh environment, or combining the previous challenges.

Sasken’s experience can offer solutions to these issues as we have successfully tackled challenging projects for several decades.

A closer look at Sasken offerings

We specialize in comprehensive mechanical design services. Our design principles are durability, usability, manufacturability, and eco-friendliness. Through simulations, we provide valuable insights that enable us to proactively address thermal and mechanical stress factors at the early stages of the design process.

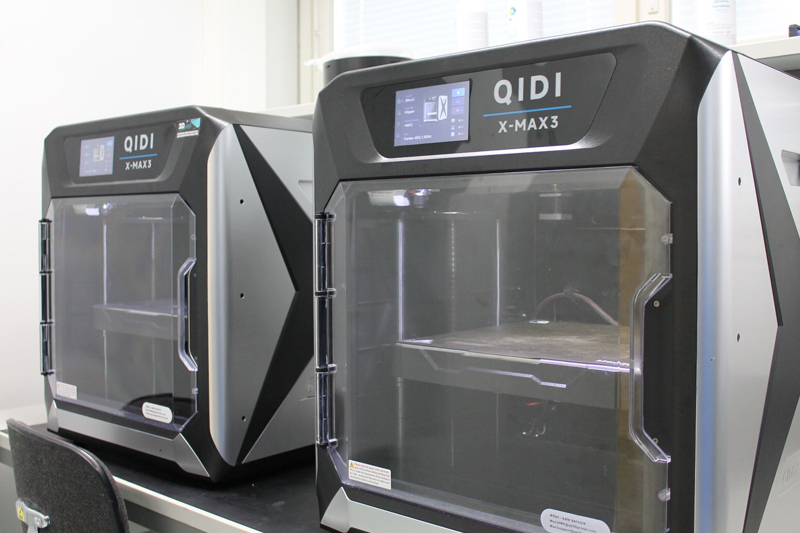

Laboratories and testing facilities

We provide production and manufacturing support, with small to medium-sized, in-house production capabilities. For mass production, we have partners who assist with large product quantities. Our on-site and off-site support for customer mass production includes yield analysis, mechanical part quality inspection for mass production, and mechanical tooling expertise.

Our small in-house assembly line aids in product assembly process verification, assembly instructions, and procedure documentation. Our in-house mechanical testing capabilities enable a fast and efficient product testing method. Our testing house partners assist with accredited testing certificates for the products.

Tools and technologies utilized

We can conduct rapid prototyping with our in-house prototype capabilities, which include SLA and FDM printing. SLA printing offers mass production-quality visuals and dozens of different material types and hardnesses, along with UV curing, while FDM printing ensures a fast and efficient verification method for product size and assembly procedures.

We offer various software solutions for migrating customer systems, such as Autodesk Inventor, CATIA V5, and SolidWorks, to name a few.